E-Track 101

Revolutionize your transportation setup with E-track, the industry standard for cargo control. Designed for versatility and durability, E-track is perfect for flatbeds, enclosed trailers, box trucks, and pickup beds. It can tie down cargo, equipment, vehicles, and more.

Jump to the Information You Need:

- What is an E-track system?

- Component information - including rails, straps, & accessories

- Should I use a ratchet or cam buckle strap?

- What are E-track wheel straps?

- How to install E-track?

- What fastener should I choose?

- How to use straps & accessories

- E-track vs. L-track

View / Download This Article as a PDF

What is an E-Track System?

E-track is a cargo securement system that uses mounted, high-strength steel rails with multiple attachment points. These attachment points are essentially small rectangular slots, and they can support a wide range of tie-downs.

The slots work well with E-track fittings, a type of end hardware commonly use with cargo nets, ratchet straps, and more.

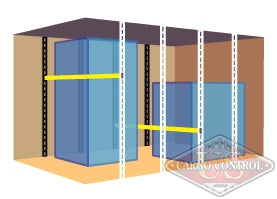

One of the major benefits of E-track is that it can be fastened to both floors and interior walls, which makes it easy to customize your cargo control. You can create horizontal, vertical, lateral, and even radial constraints to protect your product from damage during transport.

Components

E-track rails work with a variety of other components, giving you superior control over your setup.

E-Track Rails

These rails come in several lengths, and can be attached using screws, rivets, or welding. They are made of 12-gauge steel, ensuring a long life.

Rail Alignment: Vertical vs. Horizontal E-Track

The primary difference between the two styles is slot alignment. Vertical rails have slots that run parallel to the track, while horizontal rails have slots that run perpendicular.

Both can be installed on the walls and the floor of your trailer or truck and come in galvanized or gray-painted finish.

Not sure which alignment is right for you? It depends on your cargo:

Horizontal E-track is ideal for equipment and larger cargo. It has more anchor points per foot and lets you to secure cargo to the wall.

Vertical E-track provides the support needed to create a second level for cargo using shoring beams. This makes it better suited for smaller cargo – the second level allows you to make the most of your space. It also has a narrower profile so you can mount D-rings perpendicular to the floor.

Rail Finish: Galvanized vs. Painted

The main considerations when it come to choosing an E-track rail finish are price, color, and location.

If you are only looking at price, painted E-track is the way to go – it’s slightly cheaper. Its powder coat is scratch-resistant and is a matte gray color.

If you are planning on using these rails on a flatbed or any other exterior surface, you should choose hot dip galvanized. It offers protection against the elements in the form of corrosion-resistance. Galvanized rails are a reflective silver.

E-Track Singles

Don’t have enough room for a whole rail? Use an E-track single instead. It has just one slot, and can be installed in truck beds, pallets, and more.

E-Track Straps

E-track straps are tie downs made with tough 6,000 lb. polyester webbing (usually 2” wide) with an E-track fitting on one end for easy attachment and detachment.

These straps acome in different colors based on length for easy identification:

- 12’ straps are yellow

- 16’ straps are gray

- 20’ straps are blue

Strap Tightening Mechanism: Ratchet vs. Cam Buckle

What are the differences between E-track ratchet and cam buckle straps?

Ratchet straps use leverage to pull the strap very tight, making them the better option for securing large, heavy loads. They also have a higher break strength and working load limit.

Cam buckle straps rely on operator strength for tensioning, so there’s little risk of over-tightening. This makes them more suited for fragile cargo. Another benefit of cam buckles is that they are more convenient to use – they are quick to release and secure.

Load Bars / Shoring Beams

E-track-compatible load bars are square bars made of steel or high-strength aluminum that can be locked into place. Each end has an extendable fitting that you can inset into your track at the desired location.

Shoring beams are a great solution for cargo confinement – they can prevent shifting during transport. They can also be used to create more usable space in your vehicle. Just lock in multiple load bars at the same height, then lay plywood across them to create a shelf.

E-Track Accessories

You can find a wide variety of E-track accessories, letting you create your perfect tie down setup.

Tie downs without round rings are perfect for S-hooks, while spring E-track fittings have a slot for webbing so you can create a custom strap.

E-track fittings with O-rings and D-rings are great for S-hooks, flat snap hooks, and twisted snap hooks. You can also use them with your rope tie downs.

Roller idler fitting assemblies are very adjustable and are standardly used when you are going to have more than two points of contact in your restraint system, such as with vehicle tie downs.

Rope tie offs let you attach tie downs that don’t have an E-track fitting.

Wood end sockets are an alternative for shoring beams.

Don’t forget the E-track plastic end caps! They go on the ends of horizontal rails to protect from abrasions, prevent cargo and clothing from catching on the rail, and create a finished look.

More E-Track Tie Down Options

Other tie down options include cargo nets with E-track fittings and wheel nets.

What are E-Track Wheel Straps?

These straps are specifically designed for vehicle restraint. The included rubber blocks fit into the rain grooves of a tire, and the tough webbing keeps your car in place with limited bounce.

How To Install E-Track

While installing E-track in a trailer differs from installing E-track in a flatbed or other location, here are some general steps that will be applicable to many installations:

1.) Lay out the E-track sections in their approximate final location.

2.) Measure and mark where each section will be fastened. Make sure the rails are straight and aligned properly, both with the trailer and with the other rails.

3.) Mark where the trailer's underlying frame members are on the trailer surface. Depending on your installation, you may or may not be fastening your rails to the framing members. You will need to know this information either way, since it will influence your bolt placement.

4.) Put the E-track into place and begin drilling. Beginning with the end of the section, drill a hole on both sides at every fourth hole. It is not necessary or desirable to drill every hole.

5.) Insert a hex bolt into the drilled holes, through the trailer deck. From the bottom, add a washer and nut, then tighten.

6.) Install wood screws in every other empty hole, leaving one open hole between the screw and the next hex bolt.

Watch the below video for more tips on E-track installation:

Choosing the Right Fasteners

There are several common E-track fastening options, each with their own benefits. All three have a hex head, which helps to prevent slippage while driving.

Nut & Bolt Combo

This option provides the best hold using a nut, bolt, and washer. This is typically the most popular choice for installation in floors.

Self-Drilling Tip Screws

This screw is ideal for metal. The self-drilling tip allows you to skip the pre-drilling step for most surfaces.

Wood Screws

Use this style when installing on wood. The wide washer head on this screw provides superior holding power.

How to Use E-Track Straps & Accessories

It’s incredibly easy to insert an E-track fitting into a rail slot:

1.) Tilt the front end of the fitting at a downward angle and pull up on the locking pin using your index finger.

2.) Insert the front end the slot, then lower the opposite end. Release the pin.

3.) For removal, pull the release lever and lift the fitting out at an angle

Check out the video to see how it’s done!

Alternative E-Track Uses

You can use E-track in your garage, barn, worksite, and more!

You can use it to hang tools, hold feed bags, secure animal leads, mount utility carts – the opportunities are vast if you take advantage of all of the components and configurations.

Why Choose E-Track?

We’ve covered a lot of the benefits of E-track – how does that compare to other options, such as L-track?

Compared to L-track, E-track is much more industrial. It’s stronger (made with steel instead of aluminum), with a wider profile. So, if you are looking for a more heavy-duty option, E-track is the way to go.

Due to its popularity, there are also more accessories available with this track.

Questions? Ready to Buy?

Get your E-track ordered today – a lot of our products will ship the same day when ordered before 4 PM. Look for the green clock icon under the Add to Cart button!

Not sure exactly what you need? Check out our E-track kits or call to speak to one of our product experts. They’ll be happy to help answer questions, provide quotes, and place orders.

For more videos and product tips, check out the US Cargo Control Youtube channel.